Electronics Development

Our expertise and experience in electronics manufacturing flows into the development process for your new product from the very beginning. This allows us to deliver prototypes that close to being ready for serial production from the very first design cycle as part of our commitment to creating design for both manufacturability and testability (DFM and DFT). This also results in a considerable reduction in the time it takes to move from the idea to product launch.

A complete product development process is shown below, broken down into phases of the project. The EBS-SYSTART GmbH team will be glad to support you throughout the entire product development process or at just individual phases of the project.

1. Systems Analysis

With systems analysis, we concretely specify your requirements for the system being developed. We use systems analysis to ensure that all of the ways your new product will interface with your overall system are considered before getting started with serial production.

2. Requirements Analysis

Requirements analysis is conducted to specify the electronic and mechanical interfaces with the system. The result of requirements analysis is a list of specifications that will serve as the basis for all further stages of development and the basis for the final acceptance of the development results.

3. Concept

During the concept phase, technical options for realising the defined requirements are worked out. Precise block diagrams are drafted and the best technologies for developing the system are selected.

4. Development of hardware, software, logic, and mechanics

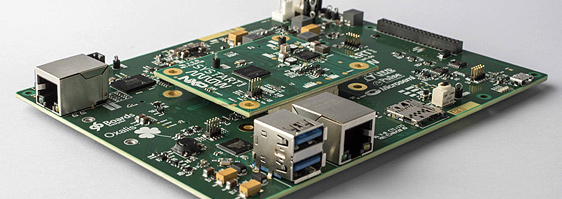

The development phase implements the identified specifications on the basis of the concept. Schematics and layouts for the modules are developed (hardware development). The logic for FPGA and CPLD is synthesized (logic development) and the embedded firmware and PC applications are programmed (software development). The mechanics are designed with the help of CAD programs (mechanics development). With a solid concept, all three areas can be developed simultaneously, resulting in excellent time-to-market.

5. Commissioning system components

Our in-house production facilities allow electronic assemblies and mechanical components to be made by suppliers quickly thanks to our rapid prototyping process. Components can be available for commissioning in just three days. During commissioning, the individual components are tested for their functionality and added to the new system components. Commission is complete once the new system component meet all of the requirements defined in the specifications.

6. Integration into the overall system

After commissioning, the newly developed system components can be integrated and tested in the overall system. This checks whether all required interfaces with the overall system function and whether the overall system behaves as desired.

7. Qualification and certification

The new system components or the new system must be certified based on the applicable standards before being launched on the market. These standards include, in particular, the various EMC directives and product safety testing rules.

The EBS-SYSTART GmbH team will be glad to support you throughout the entire product development process or at just individual phases of the project.

Your EBS-SYSTART Team