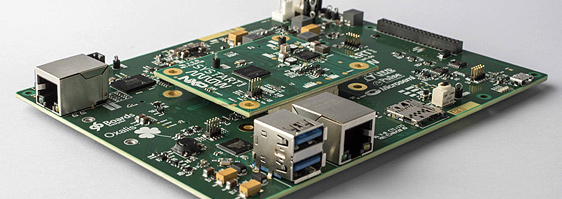

Electronics Manufacturing, Electronics Assembly, Module Assembly, SMD Assembly, THT Assembly, Small Series and Prototypes

Electronics manufacturing without one-time prototype costs

Our electronics production facility specialises in the production of prototypes and medium-sized series. We can draw on a number of assembly methods depending on the quantities involved. This flexibility allows maximum cost optimisation even for small batches or individual items. Our SMD line can assemble medium-sized series at an affordable price. In addition to THT and SMD assembly, we offer reworking and module assembly as well.

Our services and our strengths at a glance:

- Production of small- and medium series

- Production of prototypes

- Reworking and prototyping

- Rapid prototyping

- Double-sided assembly of all common circuit board types

- Affordable one-time prototyping costs

- by using inexpensive or free prototype patterns

- manual assembly saves programming and set-up costs

- SMD assembly of all component packaging types, bulk and belt sections

- testing tools developed by our own development engineers

- expert staff in electronics manufacturing for

- hand wiring

- prototype commissioning

EBS-SYSTART GmbH is your flexible partner in all areas of electronics manufacturing

Below you will read detailed information about the usual steps in our electronics manufacturing process. Other arrangements can always be worked out as required.

Component procurement and provision

Before starting with the assembly, the required components must be procured. Have us handle the materials purchasing — we have a number of suppliers with whom we have worked for many years. Of course, you can also handle the materials purchasing and simply provide us with the components for assembly.

Stencil printing

For SMD assembly, circuit boards are printed with solder paste. We use the following screen printers, depending on the lot size and other requirements:

- EKRA E4 for serial production or for prototypes with fine pitch

- Advantage: perfect print with fully automated print inspection

- For cost-effective mass production of SMD components

- PAGGEN TDS-360 for prototypes

- Advantage: inexpensive or even free templates can be used

- Printing is done manually with hand squeegees and then visually inspected

SMD and THT assembly

For the actual assembly, we use different assembly methods, either mechanical or manual, depending on the component type and number of components. This helps spare programming and set-up costs for machinery when only assembling small batches, while higher quantities are more affordably assembled by machine.

We have the following automated assembly machines:

- Siemens Siplace F4 SMD machine

- Advantage: Save time and money by fully automatic assembly of SMD components

- Optimized serial production with "only" one-time creation of a new assembly program

- Semi-automatic OK INDUSTRIES SMT-8000:

- Advantage: Precise, manual assembly of SMD components without one-time setup costs

- Optimal for prototypes and one-off production

Soldering

SMD components are reflow-soldered without oxidation and with exact temperature profiles with the Vapour Phase VP1000-66 made by ASSCON Systemtechnik Elektronik GmbH. For THT components, we use high-end soldering stations. For reworking, we also have access to a hot air station and infra-red preheaters.

Module Assembly and Commissioning

After SMD and THT assembly, the circuit boards are checked for functionality and then integrated into the overall system. We can set up work station specially designed to meet the specifications of your module assembly jobs. Your modules will be mounted and put into operation at these stations. This approach helps us ensure optimum production while maintaining quality. Each production step can be documented. A documented final assembly of your modules will always be done by our expert staff.

Packing Service

We are happy to package your products ready for sale in your custom packaging including all printed products such as product descriptions and promotional materials.

Ansprechpartner

We will handle the entire manufacturing process for your electronics products and offer you support at individual production steps. We will be glad to develop individual solutions for your needs. Contact Stephan Liedl for a no-obligation consultation.

Your EBS-SYSTART Team