Dienstleistungen

Systems Analysis

A consistent system design that precisely presents your ideas for the product to be developed provides the basis for a successful realisation of your project. We analyse your project and work with you to establish the key elements that will go into a complete list of specifications.

During systems analysis, we look at your project from different perspectives to identify the desired target system and all the ways it will interact with your system environment. This ensures that all relevant interfaces are identified and that the target system will be able to be integrated as desired into your system environment.

The procedure for systems analysis works as follows:

- formulate goals from various aspects

- define the boundaries between the target system and your system environment

- establish variants and then commit to a target system

- organise the target system into subsystems

- simulation of the subsystems and the overall system

During systems analysis, we use methods from classic systems engineering theory:

- System representation and risk analysis

- Block diagrams

- Effect diagrams

- SWOT analyses

- FMEA

- Feasibility studies

- Simulations

- Rapid prototyping

- Benchmarks

- Technology selection

- Decision matrix

- Delphi method

- EMC considerations

When addressing interdisciplinary questions, we have access to an extensive pool of experts around Munich. We would be glad to work with you on developing your desired system and thus lay the foundations to make your product a reality.

Your EBS-SYSTART Team

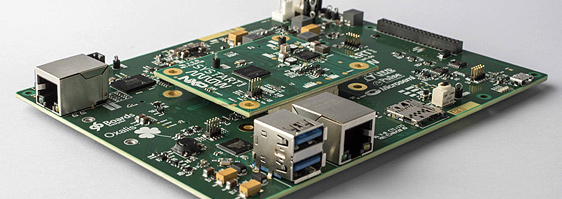

Electronics Development

Our expertise and experience in electronics manufacturing flows into the development process for your new product from the very beginning. This allows us to deliver prototypes that close to being ready for serial production from the very first design cycle as part of our commitment to creating design for both manufacturability and testability (DFM and DFT). This also results in a considerable reduction in the time it takes to move from the idea to product launch.

A complete product development process is shown below, broken down into phases of the project. The EBS-SYSTART GmbH team will be glad to support you throughout the entire product development process or at just individual phases of the project.

1. Systems Analysis

With systems analysis, we concretely specify your requirements for the system being developed. We use systems analysis to ensure that all of the ways your new product will interface with your overall system are considered before getting started with serial production.

2. Requirements Analysis

Requirements analysis is conducted to specify the electronic and mechanical interfaces with the system. The result of requirements analysis is a list of specifications that will serve as the basis for all further stages of development and the basis for the final acceptance of the development results.

3. Concept

During the concept phase, technical options for realising the defined requirements are worked out. Precise block diagrams are drafted and the best technologies for developing the system are selected.

4. Development of hardware, software, logic, and mechanics

The development phase implements the identified specifications on the basis of the concept. Schematics and layouts for the modules are developed (hardware development). The logic for FPGA and CPLD is synthesized (logic development) and the embedded firmware and PC applications are programmed (software development). The mechanics are designed with the help of CAD programs (mechanics development). With a solid concept, all three areas can be developed simultaneously, resulting in excellent time-to-market.

5. Commissioning system components

Our in-house production facilities allow electronic assemblies and mechanical components to be made by suppliers quickly thanks to our rapid prototyping process. Components can be available for commissioning in just three days. During commissioning, the individual components are tested for their functionality and added to the new system components. Commission is complete once the new system component meet all of the requirements defined in the specifications.

6. Integration into the overall system

After commissioning, the newly developed system components can be integrated and tested in the overall system. This checks whether all required interfaces with the overall system function and whether the overall system behaves as desired.

7. Qualification and certification

The new system components or the new system must be certified based on the applicable standards before being launched on the market. These standards include, in particular, the various EMC directives and product safety testing rules.

The EBS-SYSTART GmbH team will be glad to support you throughout the entire product development process or at just individual phases of the project.

Your EBS-SYSTART Team

Electronics Manufacturing, Electronics Assembly, Module Assembly, SMD Assembly, THT Assembly, Small Series and Prototypes

Electronics manufacturing without one-time prototype costs

Our electronics production facility specialises in the production of prototypes and medium-sized series. We can draw on a number of assembly methods depending on the quantities involved. This flexibility allows maximum cost optimisation even for small batches or individual items. Our SMD line can assemble medium-sized series at an affordable price. In addition to THT and SMD assembly, we offer reworking and module assembly as well.

Our services and our strengths at a glance:

- Production of small- and medium series

- Production of prototypes

- Reworking and prototyping

- Rapid prototyping

- Double-sided assembly of all common circuit board types

- Affordable one-time prototyping costs

- by using inexpensive or free prototype patterns

- manual assembly saves programming and set-up costs

- SMD assembly of all component packaging types, bulk and belt sections

- testing tools developed by our own development engineers

- expert staff in electronics manufacturing for

- hand wiring

- prototype commissioning

EBS-SYSTART GmbH is your flexible partner in all areas of electronics manufacturing

Below you will read detailed information about the usual steps in our electronics manufacturing process. Other arrangements can always be worked out as required.

Component procurement and provision

Before starting with the assembly, the required components must be procured. Have us handle the materials purchasing — we have a number of suppliers with whom we have worked for many years. Of course, you can also handle the materials purchasing and simply provide us with the components for assembly.

Stencil printing

For SMD assembly, circuit boards are printed with solder paste. We use the following screen printers, depending on the lot size and other requirements:

- EKRA E4 for serial production or for prototypes with fine pitch

- Advantage: perfect print with fully automated print inspection

- For cost-effective mass production of SMD components

- PAGGEN TDS-360 for prototypes

- Advantage: inexpensive or even free templates can be used

- Printing is done manually with hand squeegees and then visually inspected

SMD and THT assembly

For the actual assembly, we use different assembly methods, either mechanical or manual, depending on the component type and number of components. This helps spare programming and set-up costs for machinery when only assembling small batches, while higher quantities are more affordably assembled by machine.

We have the following automated assembly machines:

- Siemens Siplace F4 SMD machine

- Advantage: Save time and money by fully automatic assembly of SMD components

- Optimized serial production with "only" one-time creation of a new assembly program

- Semi-automatic OK INDUSTRIES SMT-8000:

- Advantage: Precise, manual assembly of SMD components without one-time setup costs

- Optimal for prototypes and one-off production

Soldering

SMD components are reflow-soldered without oxidation and with exact temperature profiles with the Vapour Phase VP1000-66 made by ASSCON Systemtechnik Elektronik GmbH. For THT components, we use high-end soldering stations. For reworking, we also have access to a hot air station and infra-red preheaters.

Module Assembly and Commissioning

After SMD and THT assembly, the circuit boards are checked for functionality and then integrated into the overall system. We can set up work station specially designed to meet the specifications of your module assembly jobs. Your modules will be mounted and put into operation at these stations. This approach helps us ensure optimum production while maintaining quality. Each production step can be documented. A documented final assembly of your modules will always be done by our expert staff.

Packing Service

We are happy to package your products ready for sale in your custom packaging including all printed products such as product descriptions and promotional materials.

Ansprechpartner

We will handle the entire manufacturing process for your electronics products and offer you support at individual production steps. We will be glad to develop individual solutions for your needs. Contact Stephan Liedl for a no-obligation consultation.

Your EBS-SYSTART Team